How bottles are made?

Injection stretch blowing bottle production

Basically, the bottle production process can be separated into 2 steps.

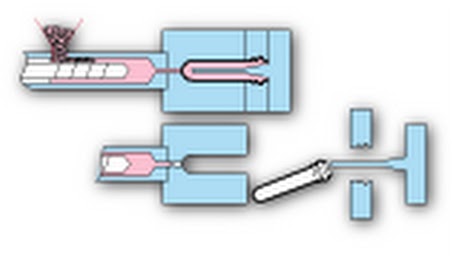

1. Preform Production by Injection

A plastic tube (Preform) is made by injection machine. Resin will be injected to be a preform. The design of preform decided the neck diameter and bottle weight of the bottle.

<injection process>

<Bottle & Preform>

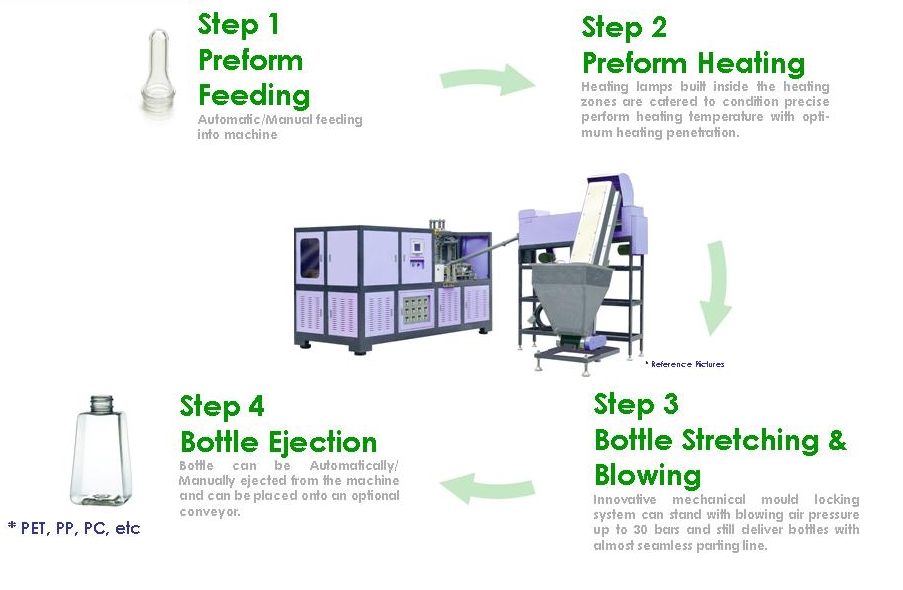

2. Reheat Stretch Blowing

Then the preform is fed into blowing machine for reheating, stretching & blowing into your required bottle shape by blow mould.

MACHINES

Hence, to produce a bottle, we mainly need two machines and two moulds:

- Preform mould for injection machine, to decide the bottle weight & neck diameter

- Blow mould for reheat stretch blowing machine, for blowing the bottle into your required shape.

We are using imported stainless steel for mould making. We also have our own engineering team for designing proper preform and blow mould, in orde to achieve high quality botle production!

BOTTLE THICKNESS & RIGIDITY

The wall thickness of bottle depends on the preform weight and bottle size. The larger the bottle, the thinner the wall thicknes, i.e. softer bottle. We may also increase the preform weight to increase the bottle wall thickness to enhance the rigidity of bottle. However, the bottle cost will be also increased as more resin is used.

updated on 2015/06/25 YT